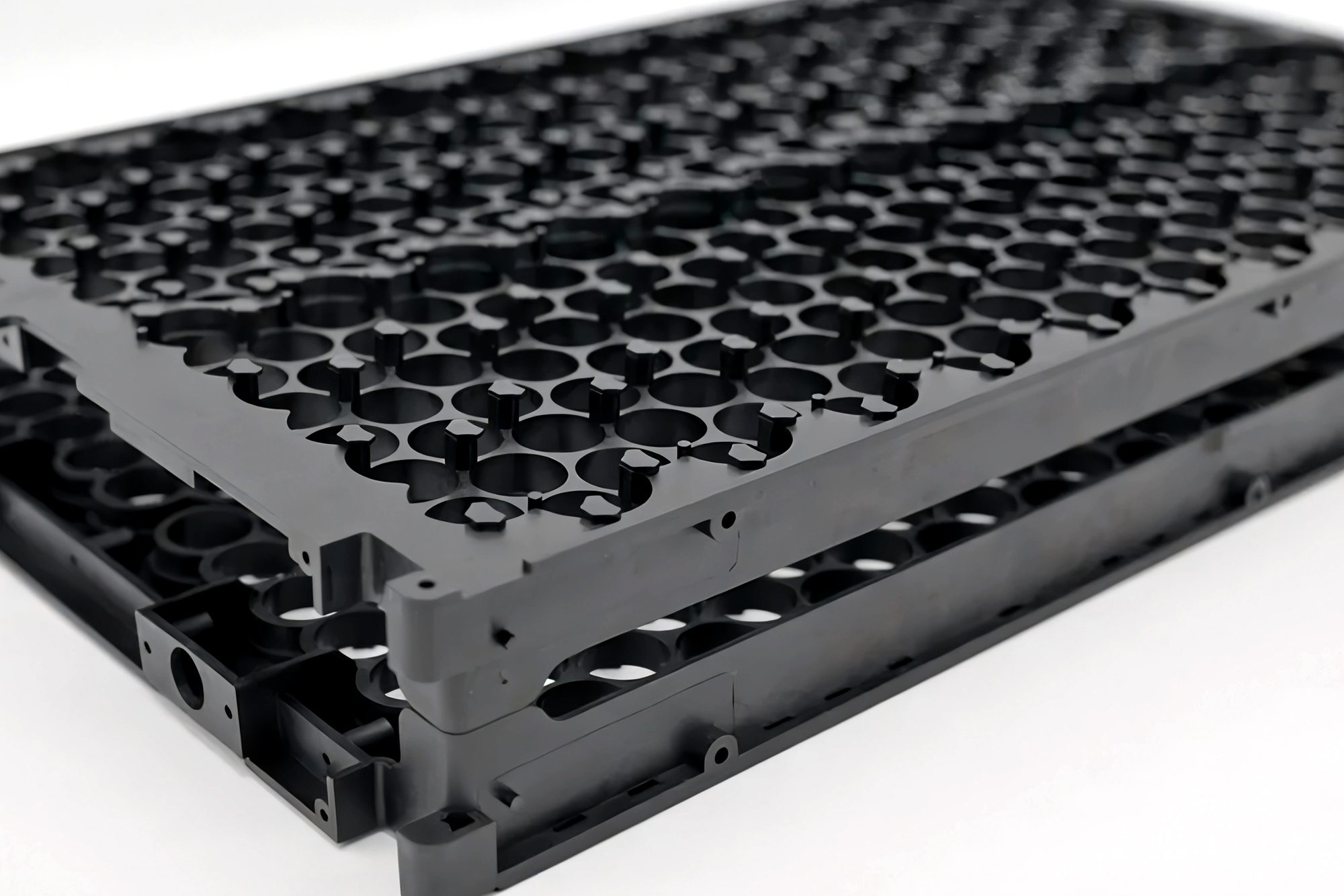

Battery Pack Mounting Bracket

In electric vehicle design, the choice of material for the battery pack mounting bracket is crucial as it needs to protect the battery from physical damage while ensuring its stability and safety. Nylon exhibits excellent heat resistance and high mechanical strength, which enables it to withstand the high temperatures that may occur during battery operation. It also provides reliable protection for the battery pack during bumps or minor collisions while driving. These properties ensure that the mounting bracket does not deform due to heat or get damaged by impact, playing a key role in safeguarding the battery’s safety and extending its lifespan.