Hotel Key Card Cleaning Machine Development Project

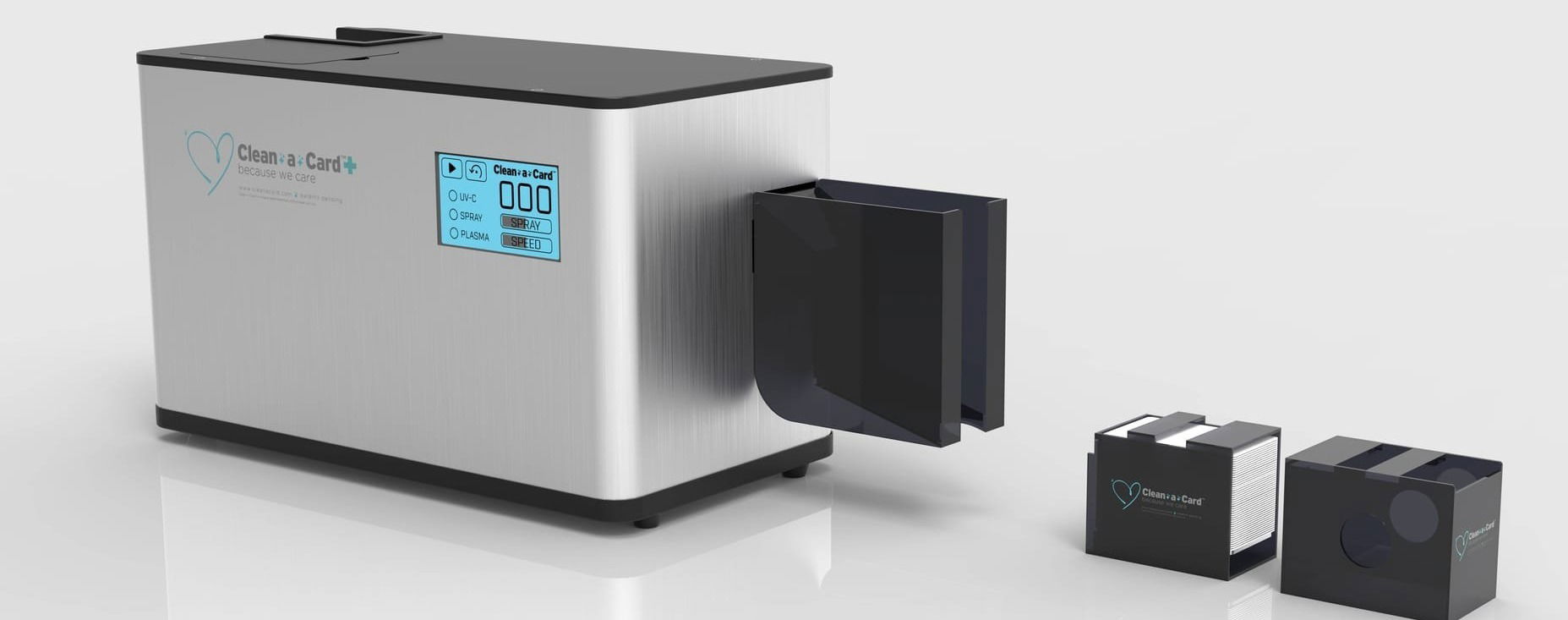

This device is specifically designed for cleaning and disinfecting hotel key cards, equipped with ultraviolet sterilization devices and disinfectant. Key cards are inserted at one end of the machine, disinfected in just 5 seconds, and then ejected from the other end.

First Prototype Ran Test

This project was commissioned by our client during the pandemic. Before they approached us, the client had already spent a year developing a prototype with another company. After taking over the project, we conducted thorough testing and deep analysis of the prototype. Initially, we planned to optimize the design of the prototype for production. However, there was a significant discrepancy between the prototype and the client's requirements, with neither the basic ultraviolet nor the disinfectant functions meeting the necessary standards.

The prototype used a very low-power UV lamp and a simple atomizer, which were insufficient for disinfection.After discussions with the client, they agreed to a complete redesign of the product. We retained some of the transmission mechanisms and part of the casing, but redesigned everything else. Given the client's desire to test the market on a small scale, and their reluctance to invest heavily in developing circuit boards and injection molds, we opted for an integrated screen control unit for the control parts; other structural parts primarily utilized sheet metal and a small amount of CNC machining.

The first prototype was completed two months later, during which our technical team worked more than 20 extra hours per week to make up for the time wasted by the previous company. The client tested this prototype and found that it largely met expectations, though the transmission mechanism was slightly unstable. Additionally, the client requested a new capability to clean 200 cards at once, up from the initial requirement of 50 cards. This significant change was unexpected but reflected the actual needs of the end users.

After modifying the design of the input and output sections, and after another month and a half of effort, we provided a new sample. The client was very satisfied with this sample and placed an initial order for 50 units. While the order quantity was not large, we treated it as a pilot production run, during which we developed numerous optimization strategies. The client planned to fully launch the product by the end of 2022, but unfortunately, as the pandemic ended, the demand for such products in hotels also disappeared.

In summary, although the project did not succeed in widespread adoption, this was mainly due to market factors beyond our control. We managed to develop a complex system product in a relatively short time, which greatly satisfied the client. Of course, all projects carry risks, and it was difficult to clearly see trends in the context of that time. Furthermore, we hope that clients will have a clear understanding of their requirements before developing a product and present them as early as possible, as major changes mid-project can waste a lot of time and effort. If you also have a product development need, please contact Ideal Pro. We offer a one-stop solution service and are a reliable partner you can trust.